-

Catalogue

- Catalogue

-

Powerscreen

- Powerscreen

-

Screening range

- Screening range

-

Chieftain Screen

-

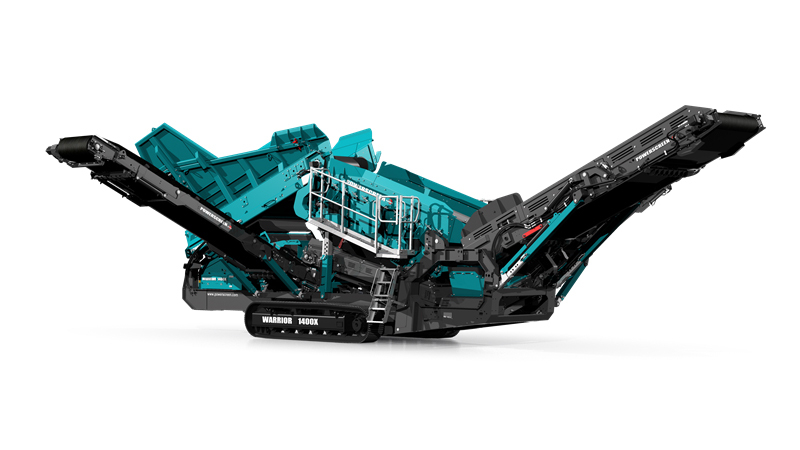

Warrior Screen

-

H-Range Screen

- H-Range Screen

- H6203 & H6203R

-

Additional Screen

- Additional Screen

- Phoenix 1600 Tracked

- Phoenix 1600 Wheeled

- Phoenix 2100 Wheeled

- Phoenix 3300

- Powertrak 750

-

Impact Crushers

-

Jaw crushers

-

Cone crushers

- Cone crushers

- 1000 Maxtrak

- 1000SR Maxtrak

- 1150 Maxtrak

- 1300 Maxtrak

- 1500 Maxtrak

-

Conveying

-

Terex washing systems

- Terex washing systems

-

Modular Solutions

- Modular Solutions

- AggreSand 165 / 206

- Aggwash 60

- Aggwash 300

- AggreScalp

- AggreScrub

-

Screening

-

Washing Systems

-

Scrubbing

- Scrubbing

- HydroScrub 200

- PS 200 / PS 200R

-

Feeding

- Feeding

- Aggrescalp

-

Stacking

- Concrete washout

- Aquamist dust suppression

-

Rubble Master

- Rubble Master

-

Crushers

-

Screen units

-

Stockpile and conveyor belts

- Stockpile and conveyor belts

- RM MTS2010S

- RM MTS2412S

-

KOMPTECH

- KOMPTECH

-

Shredding

- Shredding

- Terminator mobile

-

About

- Used machines

- Rent

- Contact Us

- KOMPTECH

Catalogue

+371 26 321 275

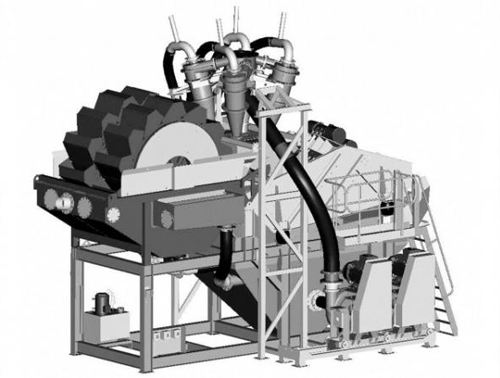

Terex Washing Systems

FM Bucket Wheel

Model description

The Terex® FM Bucket Wheel range of sand classification systems is designed as a highly efficient dewatering units. The unit removes slimes, silts and clays from sand and produces up to 2 saleable products in applications including mortar, concrete and asphalt sands, quarry dust/crushed fines, lake and beach sands, silica sand, filter bed sands, golf course sands , recycled materials and iron ore.

The range aggregates a dewatering bucket wheel(s), a centrifugal slurry pump, a collection tank, hydrocyclone(s) and a dewatering screen on a single chassis.

It is a highly comprehensive range of dewatering options for fine materials, which includes bucket wheels, screw dewaterers, bucket wheels, and hydrocyclone technologies, all proven on a global basis.

Series FM 120 BW |

Productivity Approx. 80-120 tph |

Weight 15 000 kg |

Dimensions 7.80 m x 4.4 m x 5.35 m |

Series FM 200 BW |

Productivity Approx. 120-200 tph |

Weight 17 000 kg |

Dimensions 8.6 m x 4.6 m x 7.3 m |

Features and Benefits

- Underflow rubber lined slurry pump

- Bucket wheel(s) with variable speed control

- Rubber lined hydrocyclone(s)

- Self regulating cyclone tank

- High frequency dewatering screen fitted with polyurethane modular mats

- Two grades of sand

- Weir discharge system which reduces the volume of fines entering the Cyclone collection tank

- Collapsible bucket wheel tank for easy transport (mobile only)

- Bucket wheel performs 80-90% of the work. This helps reduce the pump and cyclone size and wear

- Reduced pump and cyclone wear

- Reduced overall power requirements

- Reduced running costs

- Maximum recovery of material above 75μm (200 mesh)

- Removes silt, slimes and clays below 75μm (200 mesh)

- Removes water following dewatering operation to 10–15% of residual water content

- Major reduction in saleable material discharging to the pond, thus reducing pond maintenance and saving money

- Heavy-duty robust construction ideal for rugged operating environments

- Low maintenance

- All wear areas rubber lined

- Walkway and access ladder

- Quick assembly time